Concentrations of Chromium and Other Forgotten Things

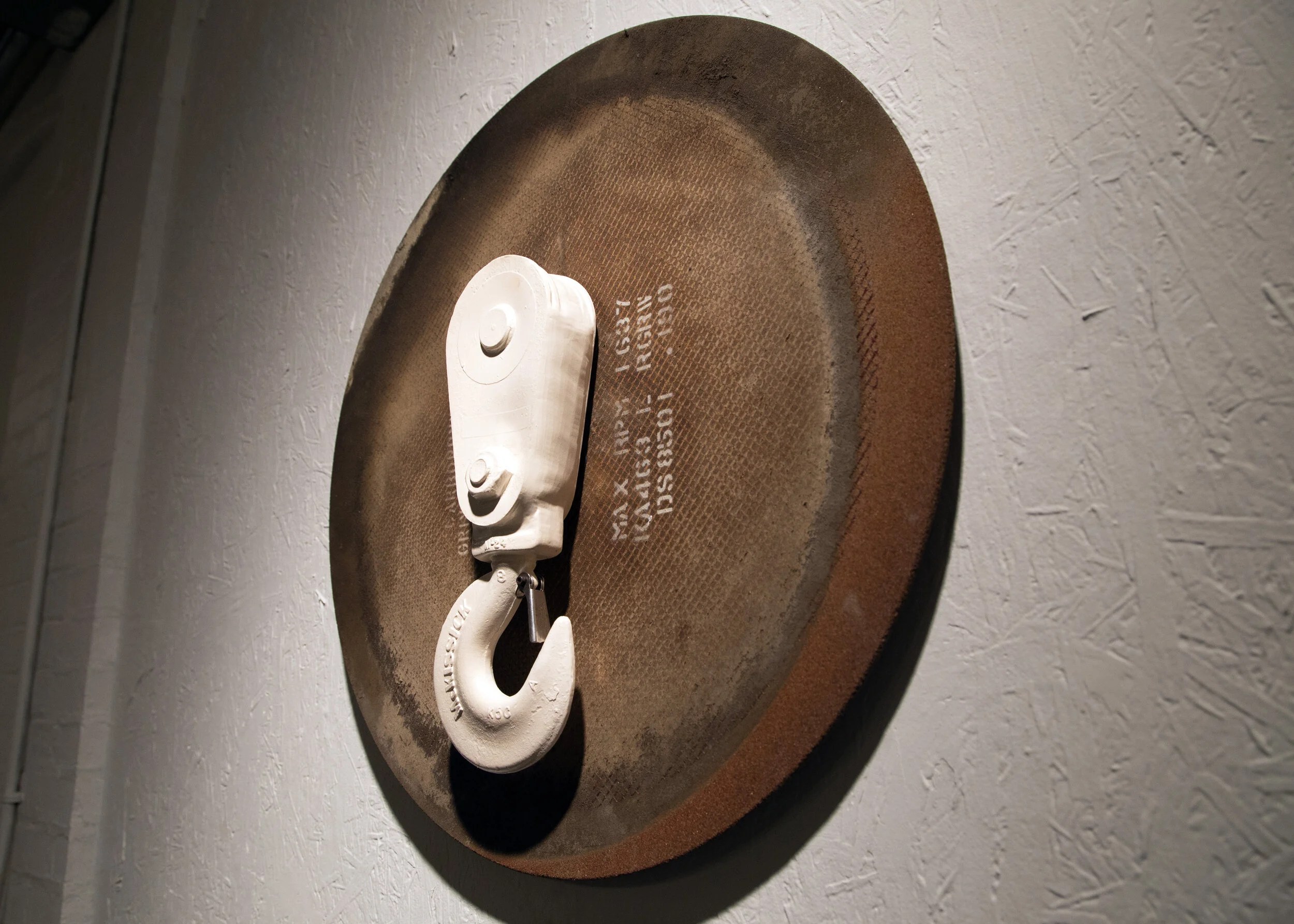

While a majority of my recent work has been about the rise and fall of the U.S. steel manufacturing industry, this exhibition focuses on how it has changed on a material level. The work is meant to honor our industrial past while also actively re-envisioning its future. While in residence at The Steel Yard, I created a new body of work to investigate the worker’s role within manufacturing in relation to technology and trade. Using a combination of chromium imagery, cast iron, porcelain, chiffon, and a reference to plastic packaging, I reflect upon the fragility of industry and the economic and evident seismic shifts that will define the future of work.

The work in this exhibition is a response to archives and objects recovered from Al Tech Specialty Steel Corporation in Watervliet, New York and hoist hooks from Providence Steel and Iron Company in Providence, Rhode Island.

The Wurks, Providence, RI